WELSIM is the #1 engineering simulation software for the open-source community.

Sunday, December 28, 2025

Compile the open-source electromagnetic simulation solver Palace

Saturday, December 27, 2025

编译开源电磁仿真求解器Palace

Tuesday, September 30, 2025

Generating Particles for Complex Geometries Using WELSIM

Monday, September 29, 2025

使用WELSIM生成复杂几何模型的粒子

Sunday, August 24, 2025

Methods for Automatic Particle Generators

Wednesday, August 20, 2025

自动化生成仿真粒子的方法

Wednesday, July 23, 2025

Orthotropic Hill Plasticity Model

正交各项异性Hill 塑性模型

Sunday, June 29, 2025

Running OpenGL-based applications in a sandbox/virtual machine

Saturday, June 28, 2025

沙盒/虚拟机中运行基于OpenGL的应用软件

Friday, June 27, 2025

Finite Element Analysis of Plastic Roll Forming

Wednesday, June 25, 2025

塑性辊压成型的有限元仿真

Sunday, May 18, 2025

WELSIM 2025R2 releases to enhance structural dynamics

The general-purpose engineering simulation software WELSIM has released its latest version 2025R2 (internal version number 3.1). Compared with the previous one, version 2025R2 contains many new features and enhancements, which can better support various types of engineering analysis, especially structural dynamics.

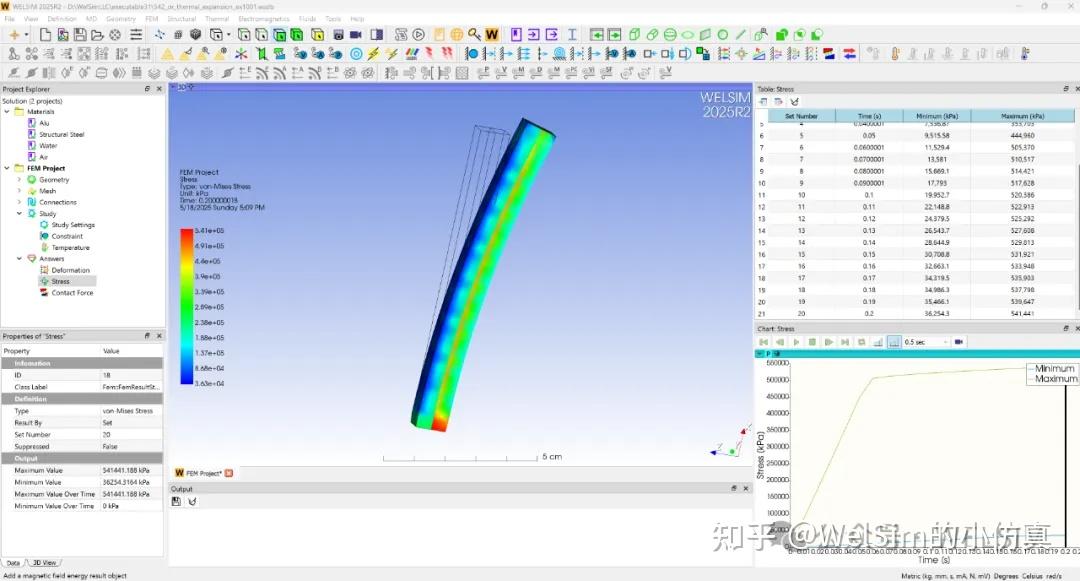

Enhance support for OpenRadioss

The new version improves the pre- and post-processing support for the OpenRadioss solver. Through support of thermal stress commands, WelSim now has the ability to solving thermal stress problems. The reading and display of contact force results have also been added. More functions such as remote displacement boundary conditions have been implemented, too.

In the material editing module, new material properties applicable to OpenRadioss have been added, such as damage plasticity (LAW23), brittle plasticity (LAW27), honeycomb structure (LAW28), Swift plasticity, Ramberg-Osgood plasticity, etc. The existing thermal expansion and specific heat material properties can output the solver command in OpenRadioss format. The independent material editing software MatEditor has also added the same function.

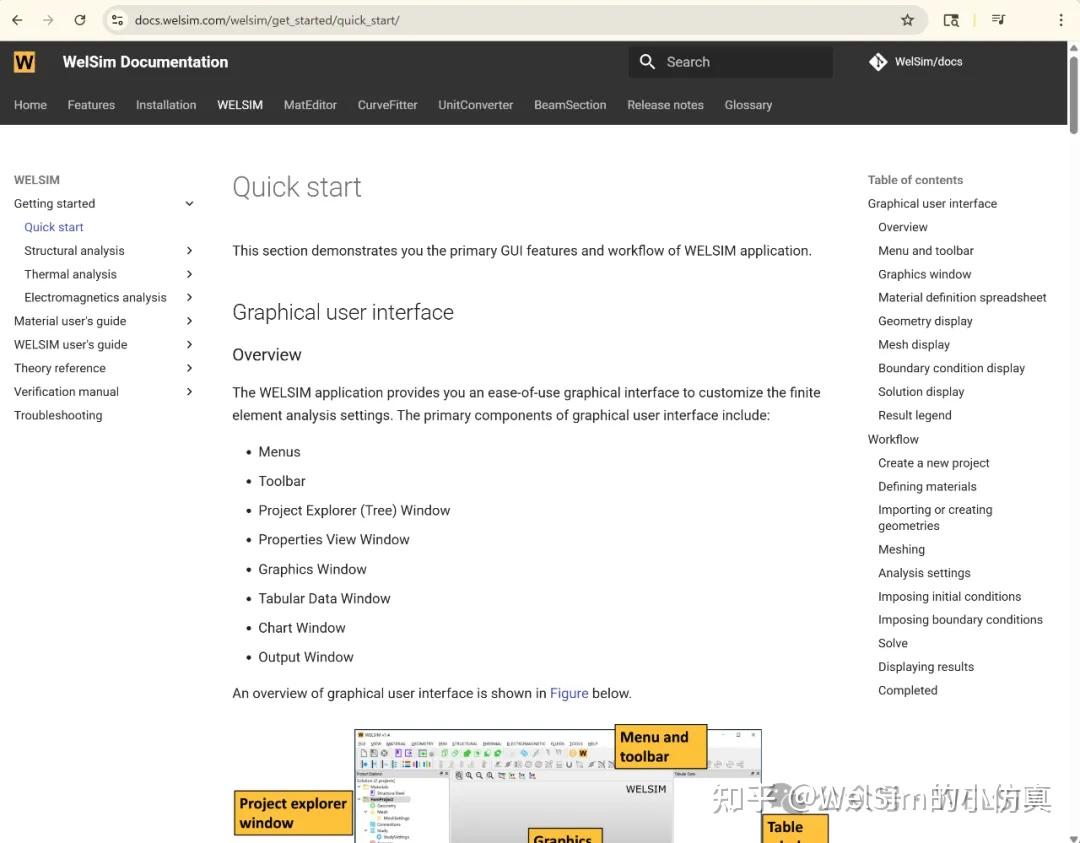

Open source WelSim’s documentation

All help documents of WelSim are open source now. This is another open source intelligent asset of WelSim, after the official website and automated testing cases. Not only can users can submit document updates about WelSim, but they can also use this framework to build online help documents for their own products. The documents are currently open source on GitHub at https://github.com/WelSimLLC/welsim-docs.github.io.

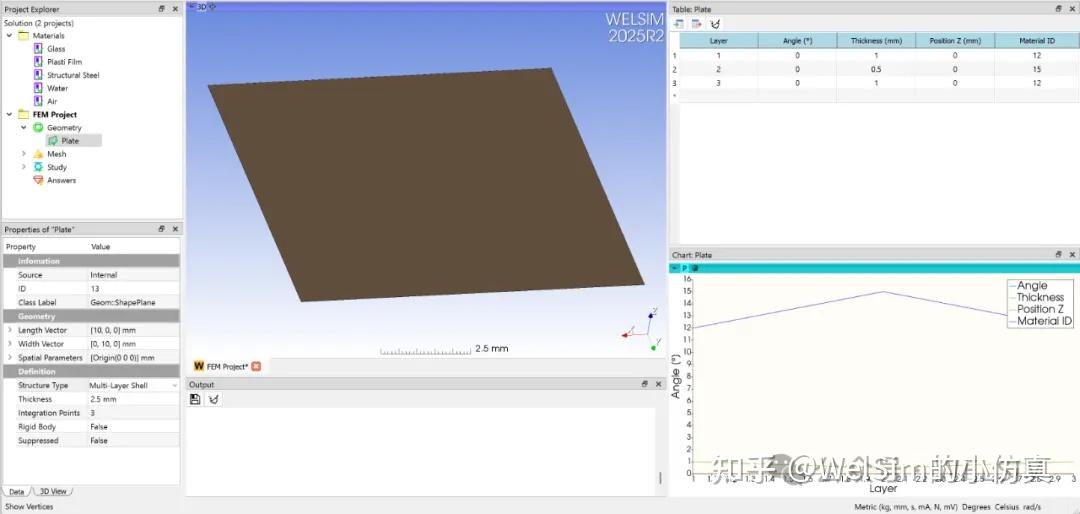

Other enhancements and upgrades

The new version has even more features and improvements. For one, WelSim now supports pre-processing of multi-layer shell structures. There have also been advancements to improve user experience: the application window title displays the full path name of the current project file, and users can now drag and drop STEP geometry files. Additionally, the CFD solver SU2 has been upgraded to the latest version 8.2. And other enhancements and upgrades.

WELSIM and the author are not affiliated with OpenRadioss, SU2. The use of OpenRadioss, SU2 is for reference in this technical blog post and software usage only.

WELSIM发布2025R2版本,增强结构动力学计算

通用工程仿真分析软件WELSIM发布了最新的2025R2版本(内部版本号3.1)。相对于上一个版本,2025R2版本含有许多新的功能与增强,能够更好地支持各种类型的工程仿真CAE分析,尤其是瞬态结构动力学分析功能。

增强对OpenRadioss的支持

新版本增强了对OpenRadioss求解器的前后处理支持。通过支持对热应力命令的支持,使得WelSim具备了求解热应力问题的功能。增加了对接触力结果的读取与显示。支持了远端位移边界条件等新功能。

在材料定义与编辑模块,增加了可应用于OpenRadioss的新的材料属性,如损伤塑性(LAW23),脆性塑性(LAW27),蜂窝结构(LAW28),Swift塑性,Ramberg-Osgood塑性等。已有的热膨胀与特热材料属性可以输出OpenRadioss格式的求解器命令。独立材料编辑软件MatEditor,也同步增加了相同功能。

开源WelSim帮助文档

开源了WelSim的全部帮助文档。这是继开源官方网站和自动化测试后,又一次开源WelSim相关的知识资产。用户不仅可以提交关于WelSim的文档更新,也能够以此框架,建立自己产品的在线帮助文档。目前文档开源在GitHub上,地址为https://github.com/WelSimLLC/welsim-docs.github.io

其他增强与升级

此外,新版本还有其他功能与提升。如支持了多铺层板壳结构的前处理。软件窗口标题显示当前项目文件的全路径名称。支持拖拽导入STEP几何文件。升级SU2求解器到最新的8.2版本。等其他增强与提升。

WelSim与作者不隶属于OpenRadioss和SU2, 和以上开发团队与机构没有关系。这里引用OpenRadioss, SU2 仅用作技术博客文章与软件使用的参考。

Saturday, April 12, 2025

Finite element analysis of plastic deformation using WELSIM

Plastic deformation refers to the process in which a structure experiences external stress beyond its yield limit, transitioning from elastic deformation to plastic deformation. This process is also referred to as elastoplastic deformation. Plastic deformation is commonly seen in industrial applications, such as the formation of various sheet metal and die casting of automobile bodies. In a professional engineering context, engineers aim to avoid plastic deformation in structures to prevent material failure. As a result, plastic analysis is very common in structural finite element analysis.

The general-purpose engineering simulation software WELSIM already supports plastic analysis. This article gives an overview of the plastic analysis features in the current version from a practical software usage perspective.

From a computational standpoint, plastic deformation is a nonlinear process in a material’s constitutive relationship. Therefore, the software must have the capabilities to solve nonlinear problems. WELSIM uses FrontISTR as its implicit solver and OpenRadioss as its explicit solver. Users can also use other solvers such as CalculiX and Elmer, which will be covered in future articles. This article focuses on the FrontISTR and OpenRadioss solvers.

Most of the complexity in plastic deformation lies in the material behavior. Therefore, considerable effort is required for the material data input and editing. With the diversity of plastic models, the front-end interface also needs to be robust. WELSIM provides a user-friendly material editor and a fully consistent, free standalone material software called MatEditor. Currently, 25 plastic-related and 12 creep-related material properties are supported. Each property has its own parameters and editing method.

Using multilinear hardening as an example, the figure below demonstrates how to define an elastoplastic material. Basic parameters are entered:

- Density:

7.8e-7 kg/mm³ - Young’s modulus:

206.9 GPa - Poisson’s ratio:

0.29

Plastic stress-strain relationship data:

- Strain:

{0, 0.05, 0.1, 0.2, 0.3, 0.4, 0.5} - Stress:

{450, 608, 679, 732, 752, 766, 780} MPa

Static elastoplastic analysis

For static nonlinear finite element analysis, the computation is essentially implicit. Nonlinear material deformation is solved using the Newton iterative method. In the project settings, you can retain the default “Static Structural Analysis” type.

Because plastic deformation is a nonlinear process, multiple sub-steps can be set in the analysis. In this example, 25 sub-steps are used.

The other analysis settings are almost identical to those in elastic analysis.

After setting boundary conditions and running the simulation, you will obtain common results like stress and displacement. For simple models, the stress results can also reflect the plasticity.

WELSIM uses FrontISTR as the default solver for static structural analysis. Supported default plastic models include:

- Bilinear

- Multilinear

- Swift

- Ramberg-Osgood

- Kinematic Hardening

Transient elastoplastic analysis

For WELSIM’s transient structural analysis, it is recommended to use explicit method with OpenRadioss as the solver. OpenRadioss is an excellent open source solver for structural dynamics, known for reliable results, and it supports a wide variety of plastic models.

In the project settings, set the analysis type to “Transient” and enable “Explicit” analysis.

In transient analysis, it’s often necessary to set the physical time for each load step and time step. As shown in the figure:

- Total time:

0.07s - Time step:

0.0001s

After defining boundary conditions and running the computation, results can be obtained.

Supported plastic models for explicit transient analysis are given below:

- LAW2 (PLAS_JOHNS) — Density + Isotropic Elasticity + Johnson-Cook

- PLAS_ZERIL — Density + Isotropic Elasticity + Zerilli-Armstrong

- LAW22 (DAMA) — Density + Isotropic Elasticity + Johnson-Cook + General Damage

- LAW27 (PLAS_BRIT) — Density + Isotropic Elasticity + Johnson-Cook + Orthotropic Brittle Failure

- LAW28 (HONEYCOMB) — Density + Honeycomb

- LAW32 (HILL) — Hill

- LAW36 (PLAS_TAB) — Density + Isotropic Elasticity + Rate-Dependent Multilinear Hardening

- LAW44 (COWPER) — Cowper-Symonds

- LAW93 (ORTH_HILL) — Orthotropic Hill

- LAW48 (ZHAO) — Zhao

- LAW49 (STEINB) — Steinberg-Guinan

- LAW52 (GURSON) — Gurson

- LAW57 (BARLET3) — Barlet3

- LAW78 — Yoshida-Uemori

- LAW79 (JOHN_HOLM) — Johnson-Holmquist

- LAW84 — Swift-Voce

- LAW103 (HENSEL-SPITTEL) — Hensel-Spittel

- LAW110 (VEGTER) — Vegter

Note: WELSIM does not include OpenRadioss in its installation package. Users need to download OpenRadioss separately and configure its directory in WELSIM’s preferences before using it for the first time.

Conclusion

This article introduces how to use WELSIM to perform finite element analysis (FEA) on structures with plastic materials. With its excellent material editing module and powerful solvers like OpenRadioss and FrontISTR, users can carry out plastic structural analysis and obtain results quickly.

WelSim and author are not directly related to the OpenRadioss, FrontISTR, Elmer, or CalculiX development team. The reference to OpenRadioss FrontISTR, Elmer, or CalculiX is only used here for technical blog and software usage references.